First, glass deep processing

Glass deep processing

Coating of different processes on the glass surface can give the glass a colorful appearance and magical unique functions.

The glass coating equipment and process developed by Senren Machinery has been widely used in the field of glass deep processing, common application areas are:

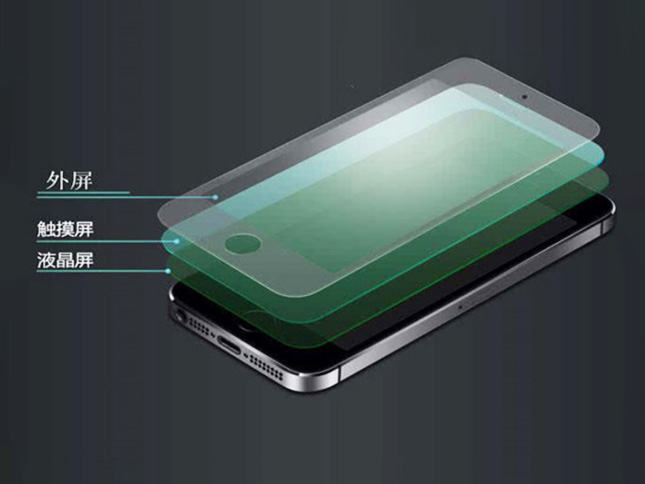

◆ Cover glass (mobile phone, tablet computer), car glass, business display glass, wearable glass, optical lens glass

◆ Photovoltaic glass (solar glass)

◆ Home appliance glass (color crystal glass) : crystal screen, TV, refrigerator, washing machine, air conditioning, microwave oven, electronic scale, etc.

◆ Architectural glass, decorative glass, art glass

◆ Smart home glass: furniture glass, switch panel glass, all kinds of smart home control panel glass

◆ Functional glass: heat insulation, UV protection, self-cleaning, conductive glass, etc.

Two, the application of Senren coating in the field of glass deep processing

The difficulty of coating ink or functional materials on the surface of glass is much higher than that of other ordinary substrates. It is necessary to solve the problems of adhesion, uniformity, flatness of the surface, and shading of the coating.

In order to achieve the ideal glass painting effect, in addition to the cleaning treatment of the glass surface before painting, the structure of the coater, the painting process and the choice of paint are extremely important.

◆ First of all, according to the technical requirements of the coating performance and the surface coating of glass products used by customers, select the corresponding coater structure and process.

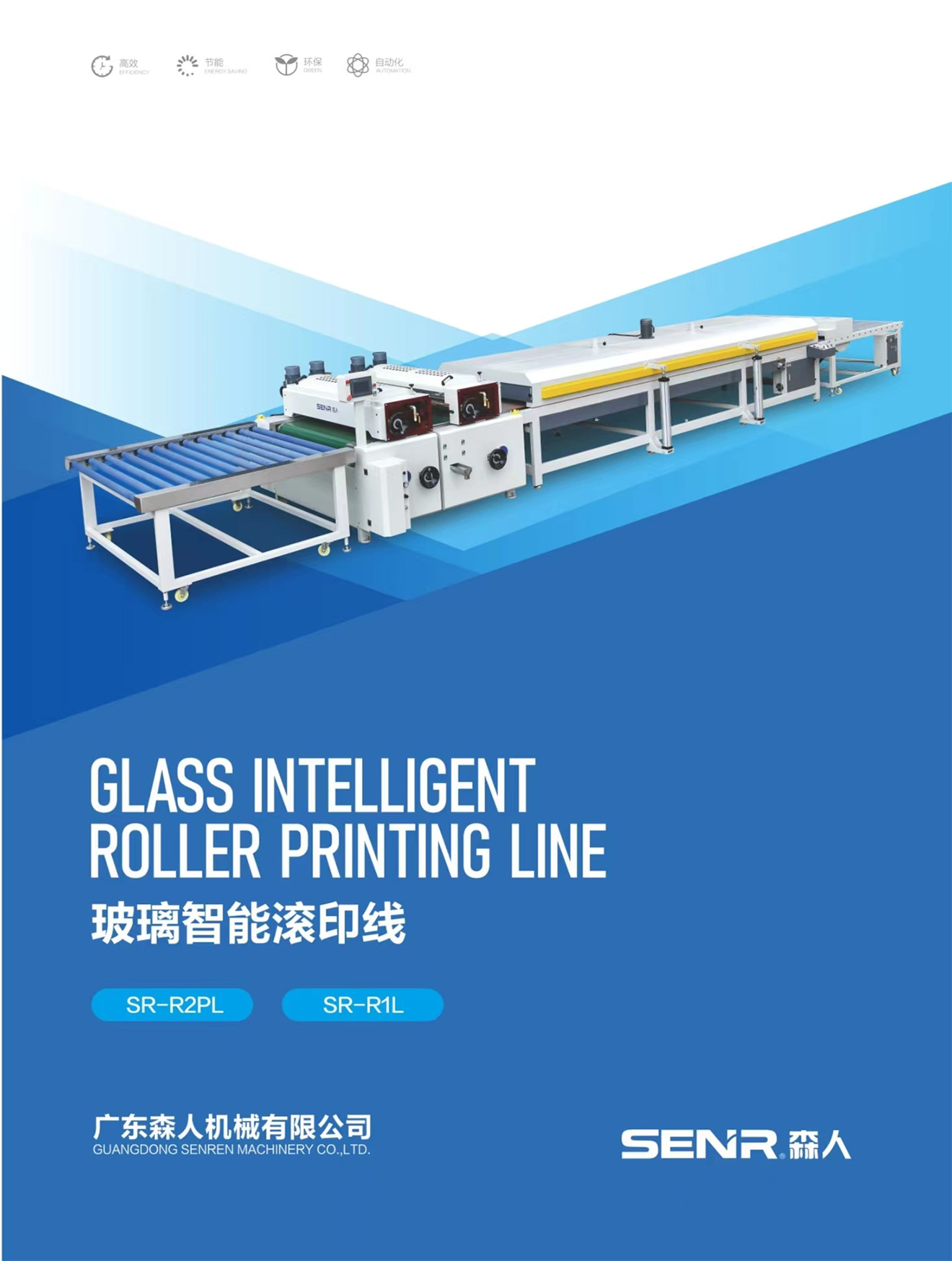

◆ The coater provided by Senren realizes full precision control, that is, the uniform wheel, the coating wheel and the conveyor belt realize independent frequency control.

◆ Depending on the properties of the coating, we can also provide infrared drying tunnel furnace or UV curing machine to realize the drying of the surface of the coated glass, so that the surface of the finished glass is smooth and smooth.

◆ Assist glass processing enterprises to upgrade

Senren has accumulated more than ten years of experience in the glass painting industry, not only has a full line of painting equipment, but also has a variety of functional coating resources, can provide complete painting solutions for users in the glass processing industry, and help users complete industrial upgrading.

For example, we can provide you with a coating line suitable for glass painting, and with a color paint that can withstand a high temperature of 700℃ and a fineness below 1nm, the ordinary glass can be directly processed into a transparent colored glass. The coating production process can avoid the shortcomings of the original sandblasted glass and acid-etched glass that are difficult to clean, and the painted glass made is colorful and more beautiful.

◆ According to the coating requirements and characteristics of colored glass, Senren machinery to provide customers with professional full-plate monochrome production equipment and process solutions. The product has the characteristics of high production efficiency, uniform coating, ink does not overflow, and has been widely recognized by domestic and foreign customers. (See website video)

◆ According to the requirements and characteristics of architectural glass and decorative glass, Senren Machinery provides customers with the most suitable production equipment and process solutions for full plate monochrome. (See website video)

In view of the market demand for large-size glass surface coating, Senren machinery has developed different series of roller printing machines with glass size width of 2400mm, 2600mm, 3000mm, 3300mm (length is not limited), which well solves many problems of difficult operation, poor screen printing effect and low efficiency of large-size glass screen printing machines. The equipment has been used stably in domestic and foreign large glass processing enterprises.