Coating the surface of the metal is a very important way to achieve special functions, anti-corrosion and beautification. A good coating layer can maintain a tight, flat and non-destructive state for a long time. The use of different functional coatings (such as insulating paint, thermal conductivity paint, heat insulation paint, sound insulation, non-stick and other coatings) to paint the metal surface can achieve different special functions, and is widely used in electronics, automobiles, electrical appliances, industry, daily necessities and other fields.

Mori's solution:

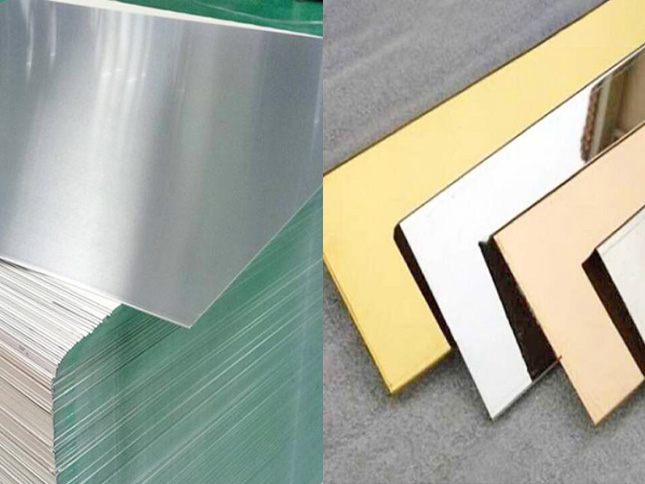

Metal coating process common roll coating, spraying, sometimes also used spray coating. Depending on the product's different requirements for coating thickness and appearance, the metal surface can be coated one or more times. Mori's metal coating equipment can meet the strict thickness and uniformity requirements.

According to customers' different product needs, Senren can provide personalized customized services, which can be applied to aluminum, copper, magnesium, iron, stainless steel, alloy and other metals.

The effect of white copper coil before rolling insulating paint

Effect of white copper coil rolled with insulating paint

Round aluminum plate for non-stick frying pans

Round aluminum roller coated with Teflon paint

Decorative iron plate painting after UV coating high light effect

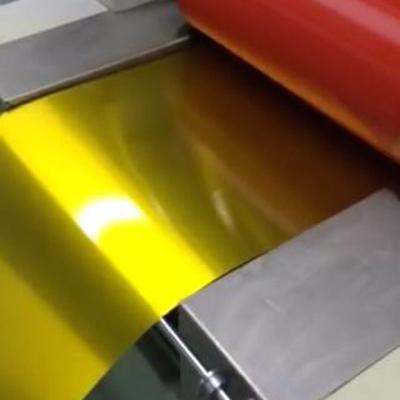

Roller coating of silicon steel

Roller coating of silicon steel

Electronic materials Aluminum coil before roll coating (unwinding)

Roller coated insulating paint

Electronic materials Aluminum roll coating (winding)

(chair accessories) Iron plate before roller coating

(chair accessories) Iron roller coated with black water-based paint

Magnesium plate roller coating exposure ink

Magnesium plate rolling exposure ink

Electrostatic spraying of hardware

Electrostatic spraying of hardware

Stainless steel plate after vacuum plating spraying anti-fingerprint paint