Coating paint layer on metal surface is a very important method for metal anticorrosion and special function. A good coating layer can maintain a smooth, non-destructive and tightly fitted state for a long time, becoming a barrier to inhibit external impurities from corroding metals. If insulating paint, thermal conductive paint, heat insulating paint, non-stick paint and other coatings are used for metal surface coating, it can achieve special functions and be used in electronics, electrical appliances, non-stick pans and other fields. In addition, colorful polyester coatings and fluorocarbon coatings can also achieve colorful decorative effects on metal surfaces, which are widely used in:

1. Metal interior decorative panel

2. Metal billboards

3. Metal suspended ceiling

4. Aluminum composite panel for building curtain wall

5. Furniture metal finish

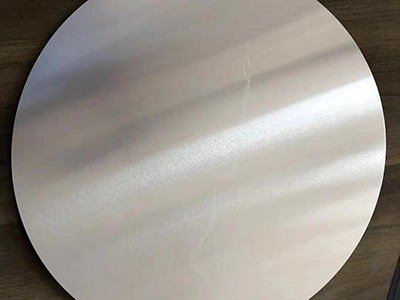

6, round aluminum plate for non-stick pan

Senren's solution

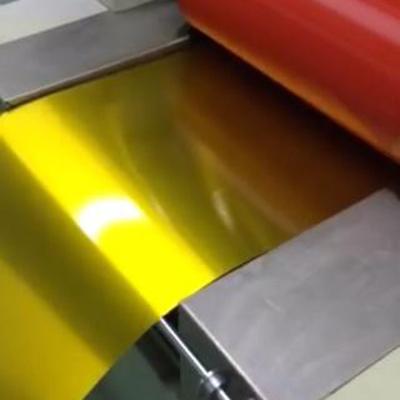

The most common metal painting process is roller coating. According to the different requirements of the product on the coating thickness, it can be rolled on the metal surface one or more times. Moreover, the whole process of roller coating is automatically controlled by computer, and the thickness is more uniform than manual spraying, which can meet stricter testing requirements. According to different production needs of customers, Senren can provide single-roller, double-roller, and three-roller coating machines for metal surface roller coating, which can be adapted to aluminum, copper, tinplate, stainless steel, magnesium and other metals. If you have higher requirements for coating flatness, we can provide a roller coater with a laser wheel as the coating wheel.

Metal painting site

High-gloss effect of decorative iron plate painting after coating with UV paint

The effect of foreign white copper coil after roller coating with insulating paint